Figure 1. Overview of DropArray Technology. A: DA-Bead 96-well photograph. The plate follows 96-well microtiter plate standard specifications and accommodates drops of

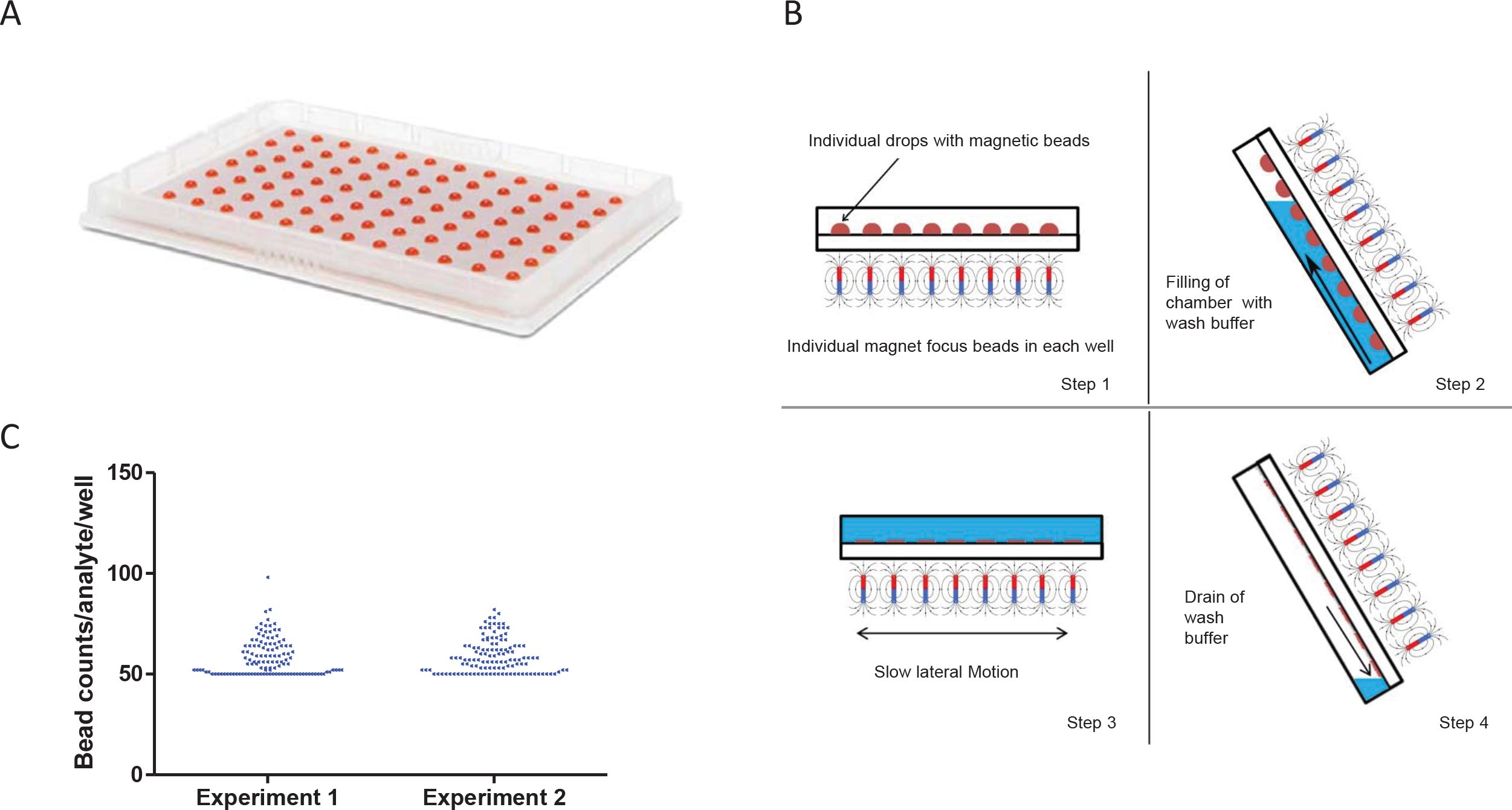

5 µl up to 20 µl in hydrophilic well space surrounded by hydrophobic polytetrafluoroethylene (PTFE) space. B: Washing principle of DA-Bead with Curiox LT-MX washer. DA-Bead plate is placed in Washer LT-MX and sealed. Each drop assay

is in line with an individual magnet, and focusing is performed for 30 s (Step 1). DA-Bead is rotated counter-clockwise to

120°, and washing buffer fills the plate from the bottom to the top (Step 2). DA-Bead is returned to the horizontal position.

The rinsing chamber is then returned to a horizontal position and undergoes low velocity lateral shaking for 10 s at a speed

of 20 rpm which is equivalent to a lateral shear force of 70.2 mm/s (Step 3). DA-Bead is rotated counter-clockwise to 120°,

and the washing buffer is drained, producing a dry plate ready for the next reagent dispensing (Step 4). C: Bead count performance of experiments presented in this study on DA-Bead. Each dot represents the count for one analyte

in a well. All bead counts are ≥50. Beads available per analyte in DA-Bead are reduced by 80% compared to conventional methods.

Figure 1 of

Le Guezennec, Mol Vis 2015; 21:1151-1161.

Figure 1 of

Le Guezennec, Mol Vis 2015; 21:1151-1161.  Figure 1 of

Le Guezennec, Mol Vis 2015; 21:1151-1161.

Figure 1 of

Le Guezennec, Mol Vis 2015; 21:1151-1161.